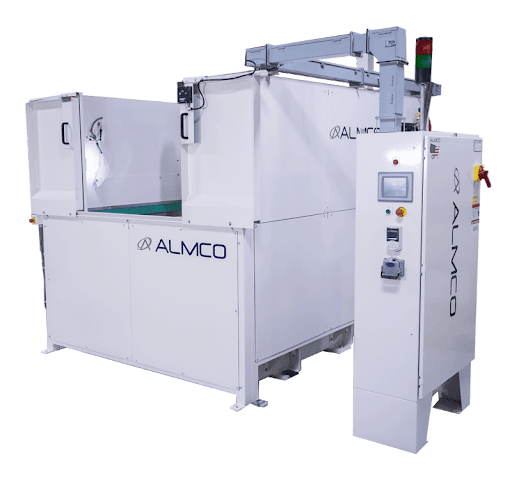

Sutton: CFT Series

The Sutton Centri-Flo machines are specialized heavy-duty spindle-finishing machines designed for high production environments. These large part deburring systems are primarily designed to finish parts such as turbine disks, blades, blisks, and impellers – with the capability of finishing many other types of parts. These machines are able to finish parts much faster than hand finishing. ALMCO offers 3 models of Sutton machines, the CF Series, CFT Series, and CFCA Series. These large part deburring systems differ from each other based on the movement of the tub and spindle.

Ideal for finishing:

- Large parts

- Parts with tight tolerances

- Parts with hard-to-reach areas

- Parts with long finishing times

- Parts that can’t be finished by hand

- Where part consistency is important

Equipment Movement:

– Tub: Vibrates. No rotation.

– Spindle: Rotates and moves in various angles and directions.

Spindle Orientation

– Mostly vertical

Sutton Machines differ from a Spindle Machine based on the size and weight of the parts they typically accommodate. See chart below for example.

|

Machine |

Part Diameter |

Part Height |

Part Weight |

|

Sutton |

Up to 55” dia |

12” Tall |

Hundreds of lbs |

|

Spindle |

Under 12” dia |

4” Tall |

<50 lbs |

Note: the chart provided above indicates the size of the parts that fit in the largest Sutton machine. This is not true for each Sutton Series.