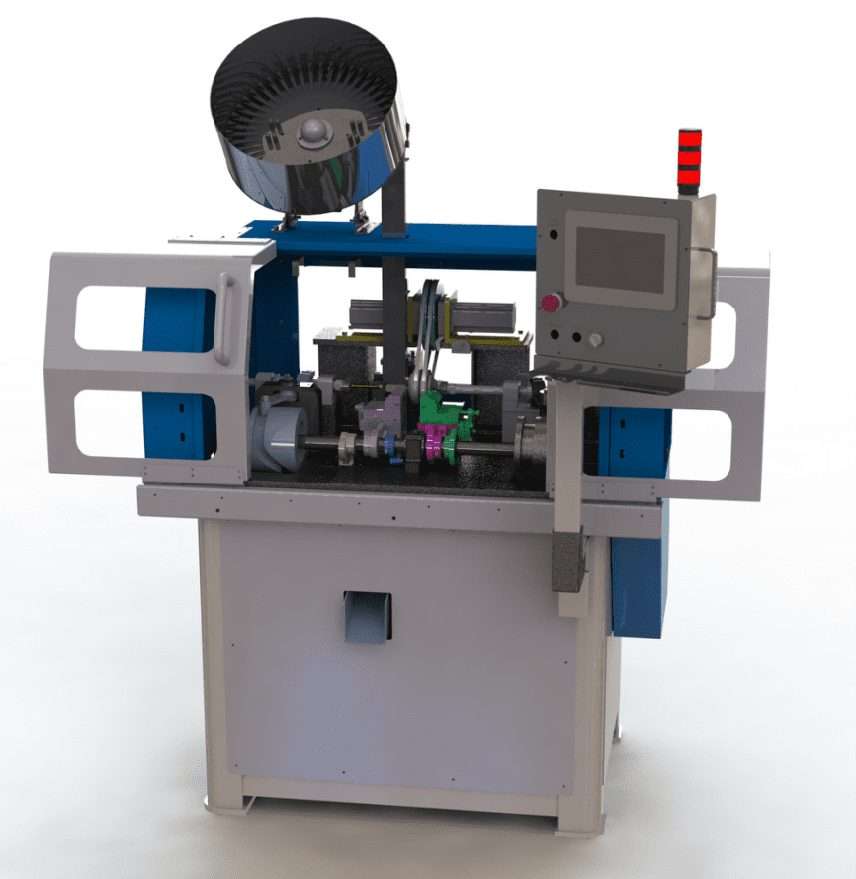

OTM-4250

The OTM-4250 is a state-of-the-art machine engineered to significantly enhance production efficiency and minimize downtime. Here’s an in-depth look at its standout features and advantages:

1. Advanced OTM-200A Feed System:

– Standard 20” Feeder: Comes equipped with a reliable 20” feeder.

– Proven Reliability: Known for its safety, reliability, and effectiveness in maintaining high production rates.

– PLC Control: The feeder is controlled via the main Programmable Logic Controller (PLC).

– Low Bowl Indicators: Alerts operators when refilling is needed, enhancing part accuracy and reducing case wear.

2. Single Operation Efficiency:

– Streamlined Process: Combines two operations into one, eliminating the need to run parts through twice.

– Double Output: This consolidation doubles the output compared to traditional methods.

3. Boosted Production Rates:

– Conventional vs. OTM Method: Traditional methods require two separate machines running at 60 PPM (parts per minute) for head turn and trim operations as the OTM utilizes only one machine.

– Optimized Floor Space The OTM-4250 uses half the floor space to achieve 60 PPM of fully processed cartridges per machine.

4. Designed for 24/7 Production:

– Minimized Downtime: Built for continuous 24/7 production to reduce downtime.

– Reduced Jam Points: Focus on minimizing jam points and operator adjustments.

– Less Physical Labor: Reduces the need for physical labor and tooling changeovers.

– Robust Safety Features: Incorporates effective safety features and mechanisms for consistent operation.

The OTM-4250 is a revolutionary machine in manufacturing technology, designed to maximize productivity while ensuring high safety and reliability standards. Its efficient design and operation make it the ideal choice for companies looking to enhance output and minimize downtime.