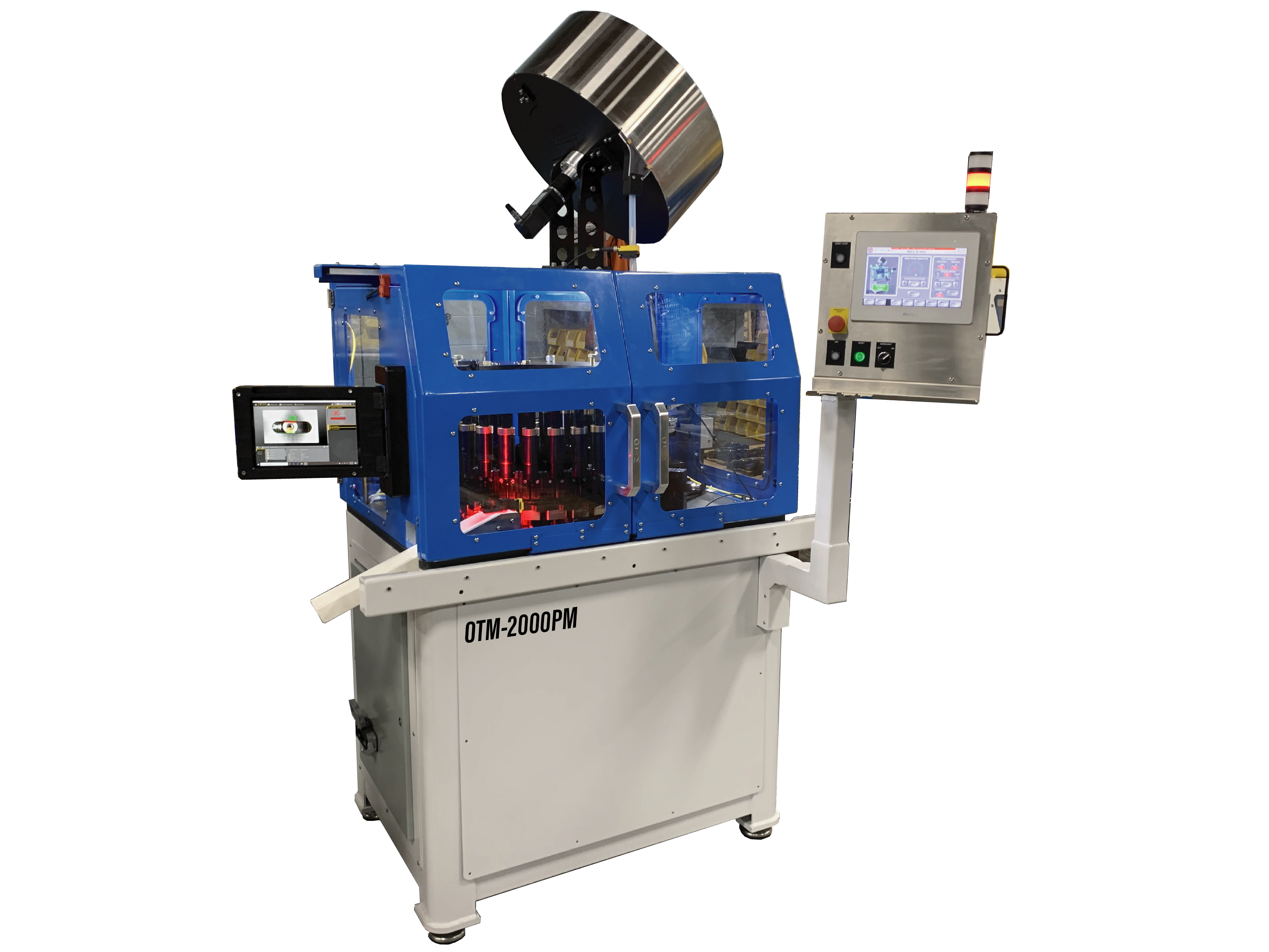

OTM-2000PM

The OTM-2000PM is a continuous motion primer insertion machine designed to revolutionize industry standards for daily operations, setup, and ease of use. This machine combines advanced technology, safety features, and robust construction to ensure high efficiency and quality in production processes.

– Continuous Motion Primer Insertion**: Ensures seamless and efficient primer insertion.

– Sound Enclosure**: Minimizes noise for a quieter working environment.

– Spring-loaded Cam**: Secures cases from above for precise primer insertion.

– OTM-240A Feed System**: An industry-proven system known for its safety, reliability, and efficiency, maintaining high production rates.

– Visual Primer Inspection**: Checks for upside-down or missing primers to ensure product quality.

– Quick Change Tooling**: Facilitates easy and fast changeovers for different calibers.

– CAM Cartridge Insert**: Factory-set at a 1 to 1 ratio for optimal performance.

– Stack Light Indicators**: Provide visual cues on the machine’s status to the operator.

– 7” Touch Screen PLC/HMI**: Offers intuitive controls and easy monitoring of machine operations.

– E-Stop and Safety Features**: Includes emergency stop buttons and safety measures for operator protection.

– Polycarbonate Windows**: 3/8-inch thick windows for enhanced operator safety.

– Door Safety Sensors**: Automatically shut down the machine if doors are opened, preventing accidents.

– Durable Construction**: All parts are machined from billet aluminum, steel, and stainless steel. Fasteners are stainless steel to prevent corrosion.

– Salt Bath Nitriding**: Applicable parts are treated for corrosion prevention and extended wear.

– Solid Steel Frame**: Provides a sturdy and stable base for the machine.

– Easy Maintenance**: Smooth surfaces facilitate easy cleaning and upkeep.

– On-Site Setup and Training**: Includes installation and training for operators to ensure optimal use of the machine.

– Comprehensive Product Manual**: Available in digital and hard copy, including recommended wear parts and daily maintenance guidelines.

– High Production Rate**: Capable of running at 200 parts per minute (PPM) for most calibers with a single primer bowl.

– Power Requirements**: Compatible with 480/220V power sources.

Compatible Calibers:

Pistols:

– .380 ACP

– 9MM

– 9MM Makarov

– .357 Sig

– .38 Special

– .357 Mag

– .40 S&W

– 10MM

– .45 ACP

– .44 Mag

– .44 Special

Rifles:

– .223/5.56

– 300 AAC

– 7.62 x 39

– .308 Win/7.62×51

– 6.5 Creedmoor

– 260 Rem

– 450 Bushmaster

If you do not see the caliber you are looking for, please contact us directly for more information.

| Caliber | Production Rate |

Number of Shifts |

Shift Hours |

5-day Production |

| 9MM | 200 | 1 | 8 | 480,000 |

| 9MM | 200 | 2 | 8 | 960,000 |

| 223 / 5.56 | 145 | 1 | 8 | 348,000 |

| 223 / 5.56 | 145 | 2 | 8 | 696,000 |

| 308 WIN | 100 | 1 | 8 | 240,000 |

| 308 WIN | 100 | 2 | 8 | 480,000 |

| 338 LAPUA | 70 | 1 | 8 | 168,000 |

| 338 LAPUA | 70 | 2 | 8 | 336,000 |