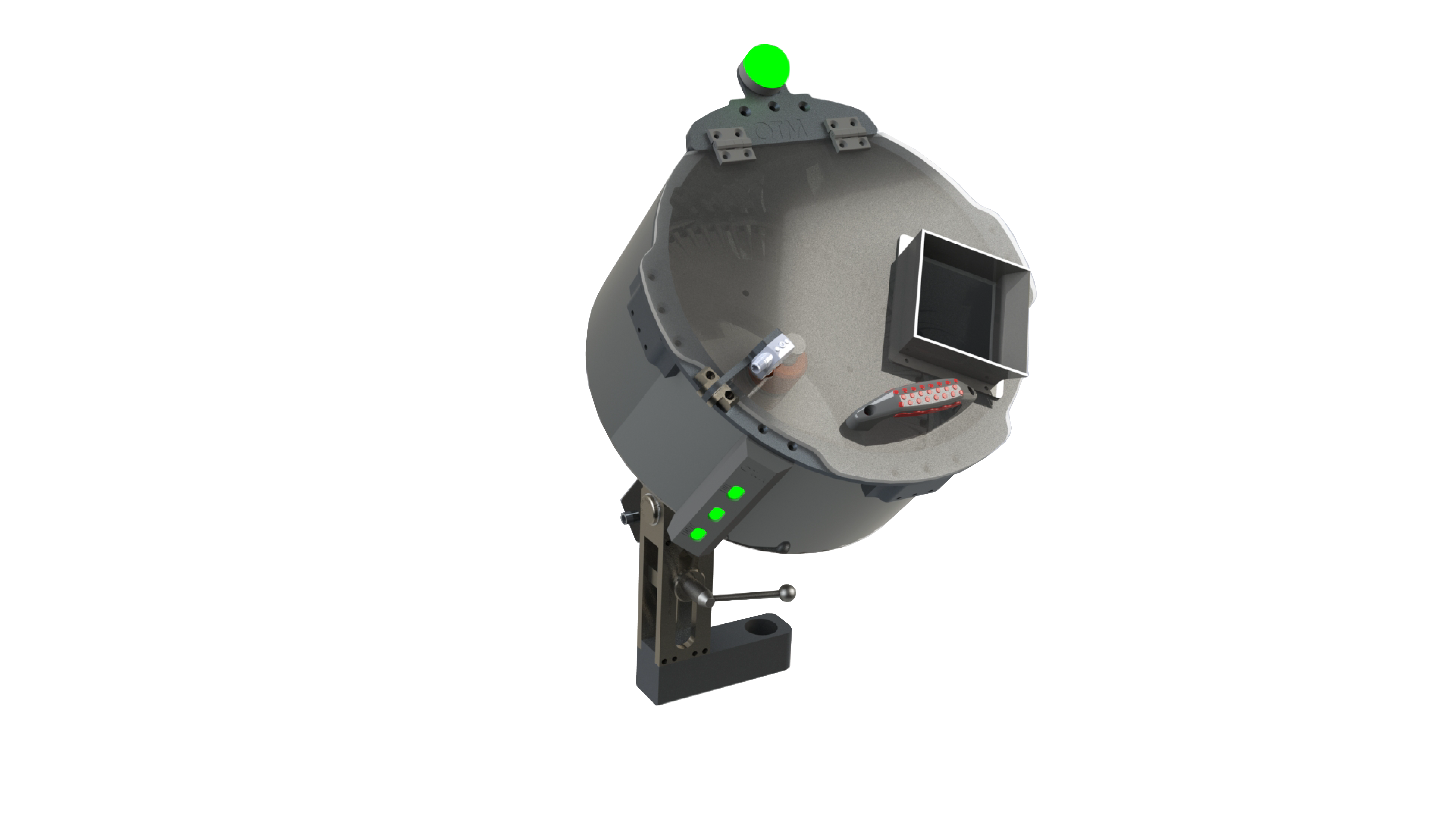

OTM-160A/B

The OTM-160A and OTM-160B models of 16″ feeders are designed specifically for smaller machines that have lower volume and feed rate requirements. These models are ideally suited for handling cases from 380 ACP to 308 Win at speeds under 100 PPM and bullets from 380 ACP to 338 Lapua at speeds under 120 PPM.

Standard Orientation of Parts:

The standard orientation for parts in these feeders is with the base or primer first. This standard orientation allows for quicker lead times on entire feed systems and makes caliber changeovers more efficient.

Standard Features:

– Stainless Steel Wall: Ensures durability and longevity of the feeder.

– Billet Aluminum Machined Components: High-quality, precisely machined components for reliable performance.

– Motor Protection System: Safeguards the motor against potential damage.

– Servo Motor with Planetary Gear Drive: Provides precise control and high torque.

– PLC Controller: Enables advanced control and automation.

– Proximity Ring Sensor: For accurate detection and positioning of parts.

– IP 65 Rated Motor and PLC Connections: Offers protection against dust and water ingress.

– Stainless Steel Hardware: Corrosion-resistant for long-term use.

– Teflon Tubing: Ensures smooth and reliable part movement.

– Caliber Change Over Kit (Handles/Shims): Facilitates easy and quick caliber changes.

Additional Features (Available at Extra Charge)

– Black Hard Coat Anodize: Enhanced surface protection for the feeder.

– Stands with Custom Colors: Customizable stands to match specific requirements or branding.

– Custom Drive Shaft/Motor Mount Plate for OEM’s: Tailored solutions for original equipment manufacturers.

– Custom Part Orientation: Specialized orientation of parts as per user requirements.

– Custom Part Discharge: Customized discharge solutions to fit specific needs.

These feeders are built to deliver efficient, reliable performance for smaller-scale operations, making them ideal for applications requiring low to moderate throughput. The combination of standard and additional features ensures that they can be adapted to meet a wide range of specific requirements.