Head Turn & Trim

In ammunition manufacturing, “head turning” and “trimming” are crucial processes for ensuring the precision and reliability of cartridge cases. Head turning involves machining the base of the cartridge case to achieve a uniform shape and size, ensuring a proper fit and primer seating. This process typically uses cam-operated machinery for precision. Trimming, on the other hand, cuts the cartridge case to the exact required length, ensuring consistent chambering, firing, and extraction, and also employs automated, cam-operated machines for accuracy.

On the Mark’s Head Turn and Trim machinery addresses many of the industry’s issues with head turning and trimming by providing a comprehensive solution within a single platform. This integrated approach streamlines the manufacturing process, enhancing efficiency and consistency in producing high-quality ammunition.

With multiple configurations, Finishing Rx can assist in meeting your facilities specific needs. Contact us now to discuss your Head Turn & Trim project.

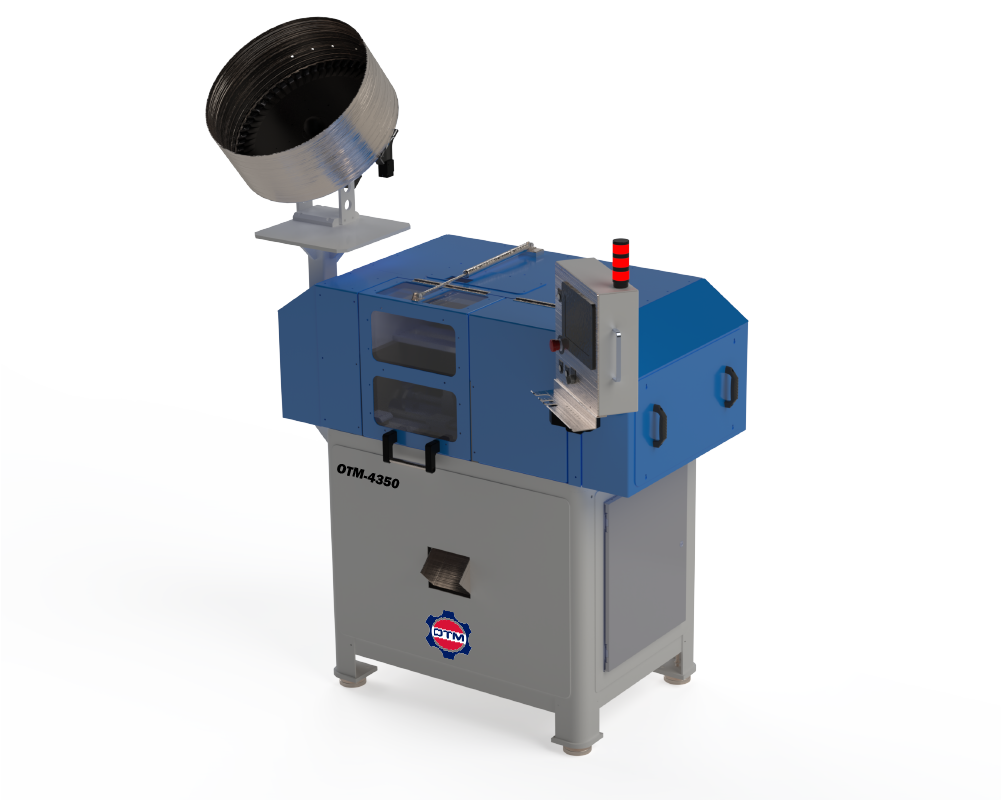

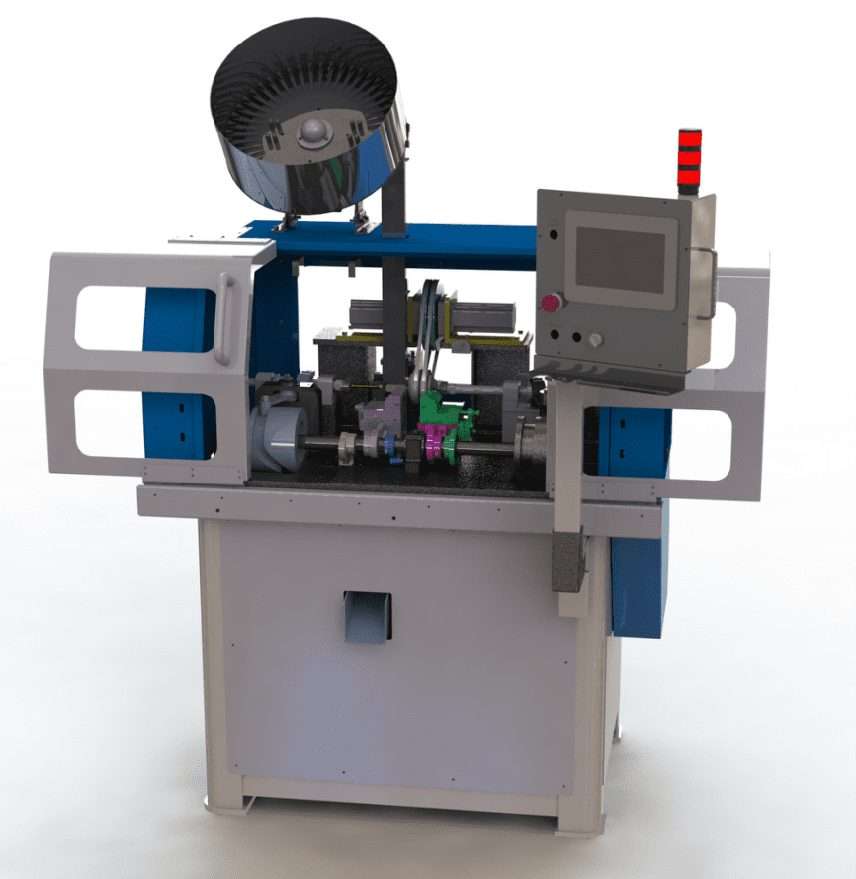

OTM-4300/OTM-4350

The OTM-4300 and OTM-4350 machines are revolutionizing the industry by addressing common challenges with head turn and trim in a single, versatile platform. The OTM-4300 is tailored for pistol calibers, while the OTM-4350 is designed for rifle calibers. Both models...

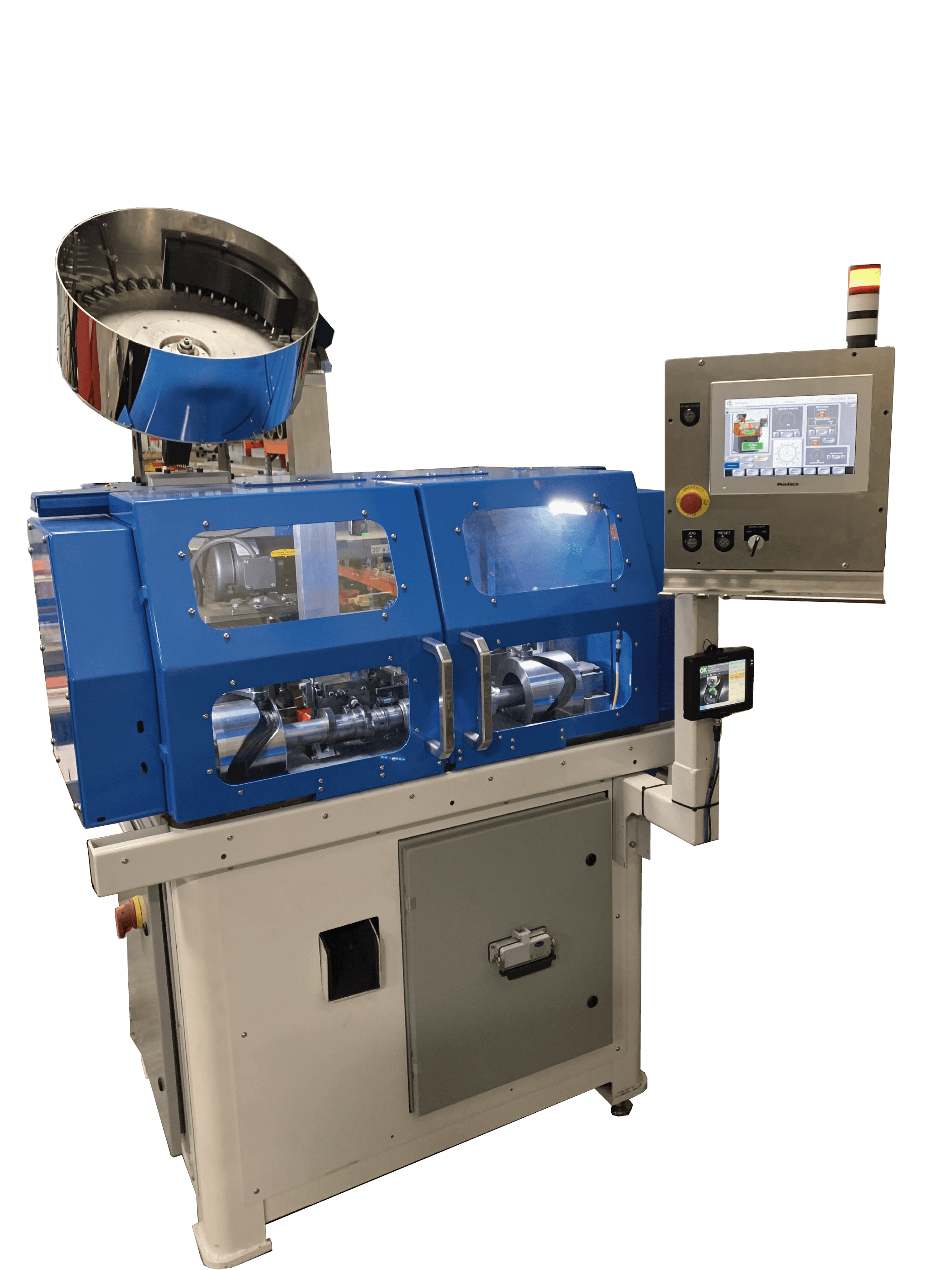

OTM-4250

The OTM-4250 is a state-of-the-art machine engineered to significantly enhance production efficiency and minimize downtime. Here's an in-depth look at its standout features and advantages:Top Features of the OTM-4250: 1. Advanced OTM-200A Feed System: - Standard 20”...

OTM-4000

The OTM-4000 is a highly advanced machine that combines the functionalities of two separate machines by simultaneously turning the head and the mouth of the case. Benefits: 1. Efficiency: Combines two processes into one, improving productivity. 2. Longevity:...