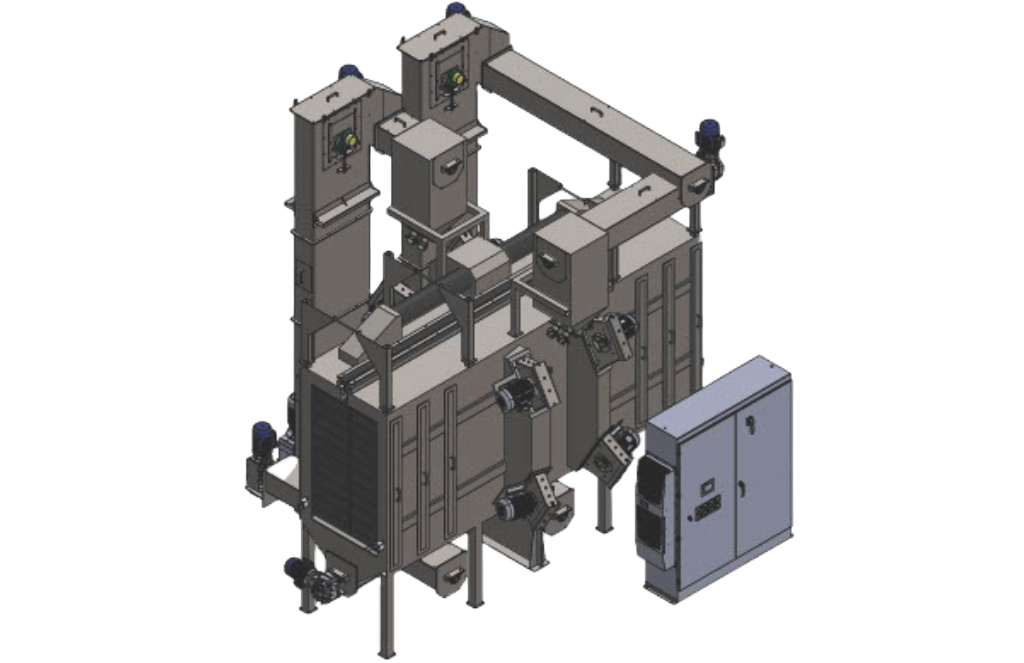

CARDINAL 48×60 Monorail System

Discover the pinnacle of shot blasting technology with Finishing Rx’s revolutionary monorail systems, custom-built to meet the unique demands of your project. Our state-of-the-art monorail-style shot blasters—also known as continuous hook or monorail hook blasters—are essential for surface preparation across a wide range of industries. These sophisticated machines facilitate automated, uninterrupted processing by transporting workpieces through a continuous loop or track, ensuring a steady flow that minimizes downtime and maximizes output. This automation not only enhances efficiency and ensures uniform processing but also significantly reduces manual labor and human error, boosting overall safety standards.

At the heart of our shot blasters lies the blasting chamber, where the magic happens. Equipped with high-velocity blasting wheels or nozzles, the chamber propels abrasive media onto the workpiece, ensuring comprehensive coverage and uniform treatment. Designed to contain the abrasive media and prevent dust and debris from escaping, the chamber maintains a safe and clean working environment, protecting both equipment and personnel. Constructed from wear-resistant materials, it guarantees long-term reliability and reduces maintenance costs. Reach out to Finishing Rx to explore how our custom-built monorail systems can elevate your production process to new heights!

– (8) 20HP Direct Drive Blast Wheel Assy.

– Two Single Lip Separator

– Low Level Sensor, Shield, Indicator light

– Elevator Belt with Cast Buckets

– Hour Meter, Amp Meters, Digital Blast Cycle Timer

– Entrance Vestibule Included With (3) Sets of Seals in Each

– Exit Vestibule Included With (3) Sets of Seals in Each

– Manganese Blast Cabinet with Cast Lining, Opposite the Blast Wheels

– Rotary Screen

– 55-Gallon Barrel Adder Hopper Included with Low Level Sensors

– Blow Off Vestibule with Blow Off System

– 480volt/3Phase/60Hertz Electrical Panel with 120 Volt Controls

– Recipes for PLC (5 Included)

– Dust Collector Control Circuit

– Requires 16,000 CFM Dust Collector

CENTRIFUGAL BLAST WHEEL

WHEEL: An efficiently designed single-sided blast wheel minimizes the overhung load on the motor and reduces the time required to change blades, impellers, and control cage. The standard blast wheel measures 15” in diameter and features seven curved blades for optimal abrasive control. All components are balanced to ensure smooth operation. With a high horsepower-to-weight ratio, this system enhances abrasive delivery efficiency per unit of horsepower.

MOTOR: Direct drive motor revolves at 3600 RPM. Taper lock brushed motor shaft with NEMA tolerance.

BLADES: Our innovative Snap Lock system simplifies blade replacement without the need for tools. Crafted from abrasion-resistant alloy in our in-house foundry, our curved blades offer optimal abrasive control. Cardinal shot blast wheels allow for effortless blade replacement in sizes 12”, 13.5”, or 15”, enhancing shot velocity and increasing versatility.

CONTROL CAGE: Dial type cage for ease of targeting the abrasive flow.

WHEEL HOUSING: Our wheel housings are made from durable steel plate and are fully lined with replaceable cast chrome manganese alloy liners produced in our own foundry.

CABINET CONSTRUCTION

CABINET This innovative pitless design is crafted from a sturdy 1/2” Manganese plate, ensuring exceptional durability. Its interior features high-quality cast liners in the blast zone for superior protection and extended lifespan. These liners are engineered to withstand extreme conditions, ensuring reliable performance and reduced maintenance.

VESTIBULES Our entrance and exit vestibules are meticulously designed to maximize shot retention. Each vestibule features three sets of media containment seals to ensure optimal efficiency. Strategically placed the multiple layers of containment minimize shot escape and improve safety.

WORK HANDLING

MAXIMUM WORKING DIMENSIONS 48” Wide x 60”Tall

ABRASIVE RECYCLING SYSTEM

ELEVATOR: Our belt and bucket elevator features centrifugal discharge and is outfitted with an elevator belt along with cast buckets. The screw-adjusted shaft take-ups guarantee accurate belt alignment. The abrasive shot blast media is efficiently conveyed by the buckets to the hopper positioned above the machine, where the media will flow to the shot blast wheel.

CABINET SCREEN The Rotary Screen consists of a metal drum with 1/4″ perforations and an internal auger, specifically designed to effectively screen larger debris from the Media and discharge it out of the system. The screened Media then proceeds through to the hopper. In the presence of the rotary screen, the primary lower screen is 1” mesh size for enhanced screening efficiency.

ABRASIVE CONTROL VALVE: Totally enclosed butterfly valves are air cylinder operated. Fully adjustable for abrasive flow control.

ABRASIVE SEPARATOR: The Single Lip Separator, also known as a media air wash, efficiently removes fines and dust from blasting media, ensuring only clean, heavy media is recycled through the shot blast wheel. As media is returned to the hopper above the blast wheel, it spreads into a waterfall, creating a thin blanket of flowing media. A dust collector then pulls air across this stream, eliminating unwanted particles and allowing clean media to return to the abrasive hopper, ready for reuse. This process maintains high-quality blasting media, enhancing the effectiveness and longevity of the blasting operation.

ABRASIVE REQUIRED: 20,000 pounds.

VENTILATION

DUST COLLECTION: Effectively eliminates dust-laden air from the machine, ensuring a cleaner work environment. It incorporates a single lip separator that efficiently separates fines and dust from larger abrasives, keeping the media clean as it is returned to the blast system. The machine requires a 16,000 CFM dust collector, sold separately. Collector control circuit pre-wired on all Cardinal Shot blasters for easy integration.

ELECTRICAL CONTROLS

CONTROL PANEL:

- Type 12 electrical enclosure.

- Thermal overload protection for all motors.

- Standard 230/460 volt ammeter.

- Oil tight push button controls.

- Timer controls the abrasive flow.

- Touch Screen PLC Controls.

SAFETY FEATURES: The blast wheel operates exclusively when the door is shut. An air lock mechanism ensures that the cabinet door remains securely closed throughout the blasting process. With an adjustable time delay feature, the flow of abrasives serves as a brake on the blast wheel before the door can be safely opened.

ELECTRIC MOTORS: All motors are totally enclosed, and fan cooled to provide maximum life. Optional 230/460 volt 3-phase.

NOISE LEVEL: Approximately 85 db.