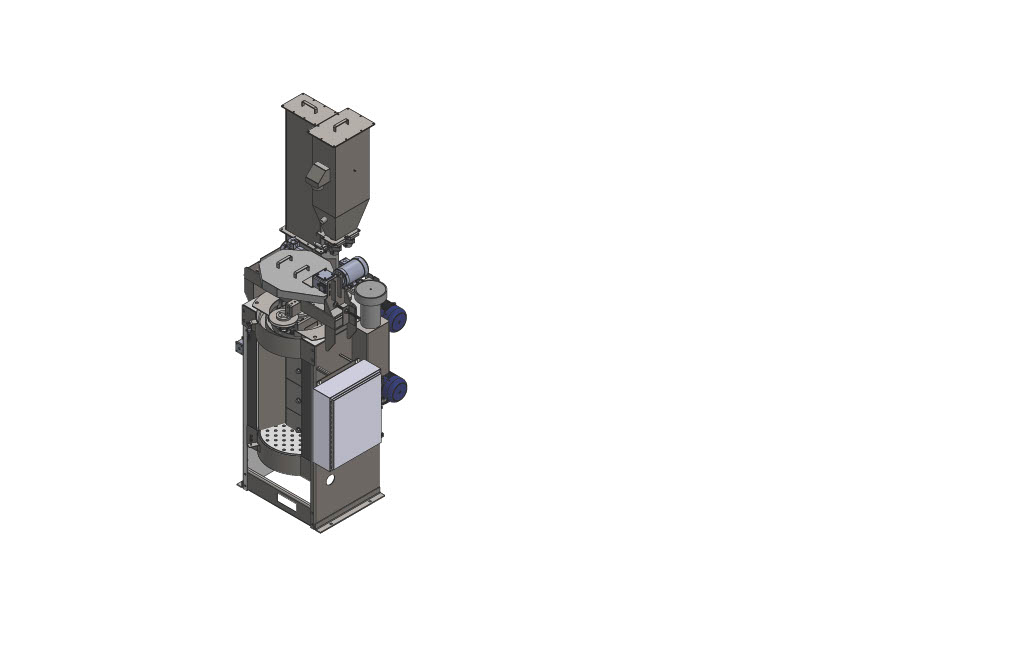

Cardinal 1244 Spinner Hanger

Introducing the Cardinal 1244 Dual-Chamber Spinner Hanger Blaster, a masterfully engineered, freestanding, floor-mounted cabinet designed to revolutionize high-production blasting. This state-of-the-art system features dual chambers that operate in unison—one dedicated to loading and unloading while the other conducts a powerful blast cycle. Upon completion, the chamber drum ingeniously rotates, seamlessly transitioning the loaded zone into the blast chamber and moving the processed zone to the operators for efficient unloading and reloading. This meticulously optimized setup ensures maximum production efficiency and a smooth, uninterrupted workflow.

Experience unparalleled coverage with parts hung onto a hanging fixture tree, which spins to expose every surface to the blast. The drum indexes during the process, allowing for multiple blast angles to achieve comprehensive results. The Cardinal 1244 Dual-Chamber Spinner Hanger boasts two robust 5 HP, 10″ diameter blast wheels—one rotating clockwise and the other counterclockwise. For enhanced durability, all carousel walls are lined with cast liners. Built from thick steel plate, Cardinal shot blasting systems promise longevity and reliability. The dual-chamber spinner hanger models are equipped with cutting-edge innovations such as PLC/HMI control, variable speed spinners and chamber drives, and robust protective linings, making them the perfect solution for the most demanding blasting applications.

– (2) 5 HP Direct Drive Blast Wheel Assy.

– (Top Wheel CCW, Bottom Wheel CW)

– Low Level Sensor, Shield, Indicator Light

– Cabinet Back Wall AR400 liners

– Cabinet Side Walls Rubber Lined

– Carousel Walls Fully Lined with cast Liners

– V-Belt with Steel Stamped Buckets

– PLC Controls, Safety Bar

– Hour Meter, Amp Meters, Digital Blast Cycle Timer

– Variable Freq. Spinner Drive

– Variable Freq. Chamber Drive

– Requires Dust Collector 800 CFM

– Dust Collector Control Circuit, up to 3 HP

CENTRIFUGAL BLAST WHEEL

WHEEL: Two efficiently designed single-sided blast wheels minimizes the overhung load on the motor and reduces the time required to change blades, impellers, and control cage. The standard blast wheel measures 10” in diameter and features four curved blades for optimal abrasive control. All components are balanced to ensure smooth operation. With a high horsepower-to-weight ratio, this system enhances abrasive delivery efficiency per unit of horsepower.

MOTOR Direct drive motor revolves at 3600 RPM. Taper lock brushed motor shaft with NEMA tolerance.

BLADES: Our innovative Snap Lock system simplifies blade replacement without the need for tools. Crafted from abrasion-resistant alloy in our in-house foundry, our curved blades offer optimal abrasive control. Cardinal shot blast wheels allow for effortless blade replacement.

CONTROL CAGE Dial type cage for ease of targeting the abrasive flow.

WHEEL HOUSING Our wheel housings are made from durable steel plate and are fully lined with replaceable cast chrome manganese alloy liners produced in our own foundry.

Blast Cabinet Crafted from durable ¼” steel plate, our cabinet construction promises unparalleled durability and reliability. Thoughtfully designed access doors allow for maintenance efficiency. Additionally, tramp metal is effectively captured on lower abrasive screens, ensuring that large debris is meticulously filtered out before it can reach the abrasive hopper, maintaining optimal blasting performance and equipment longevity.

Dual Chamber Carousel The Cardinal dual chamber spinner hangers boast exceptional quality with a structurally reinforced and fully welded carousel crafted from durable steel plate. This robust carousel rotates on a sturdy 3″ diameter shaft, bolstered by a heavy-duty thrust bearing for smooth operation. Additionally, the inclusion of hook spindles on each chamber enhances the functionality and versatility of the spinner hangers, allowing for efficient and effective hanging of items. This design ensures long-lasting performance and reliability in industrial settings.

Chamber Lining The Cardinal dual chamber spinner hangers feature carousel chambers lined with their proprietary cast alloy liners, providing exceptional durability and wear resistance. To enhance performance even further, the top and bottom of the chambers are lined with abrasive-resistant steel for added protection. For those seeking tailor-made solutions, optional liner upgrade packages are available to customize the spinner hangers to specific processes and applications, ensuring optimal performance and longevity in diverse industrial environments.

Chamber Drive : The Cardinal unique chamber drive design features an advanced carousel system powered by an electric motor and gear reducer, which activates a low-speed, high-torque “HTD” type drive assembly. This modern approach leverages PLC programming to replace outdated mechanical relays and timers, simplifying troubleshooting and maintenance. Additionally, adjustable stops on the carousel top work seamlessly with proximity switches to offer customizable indexing options.

MATERIAL HANDLING

Hook Spindle The continual rotation of the hook spindle during the blasting operation ensures comprehensive exposure of all parts to the blast pattern. This consistent movement allows for even coverage, eliminating blind spots and ensuring that every surface of the parts receives the necessary treatment. By maintaining a uniform blast, the system enhances the quality and consistency of the finish, leading to superior results. Furthermore, this design maximizes the efficiency of the blasting process, reducing the time required and improving overall productivity.

Hook Spindle Maximum area provided for material to be blasted is 12” diameter x 36” long. Optimal is 12” x 24” for top to bottom blasting. 250 pounds maximum capacity. Spindle speed, variable.

ABRASIVE RECYCLING SYSTEM

ELEVATOR The bucket elevator system features cast iron sheaves and metal-stamped buckets. Our design ensures precise tracking and simple adjustments by employing a heavy-duty C-section banded V-belt elevator belt with a multi-cord construction. The abrasive shot blast media is transported by the metal-stamped buckets to the hopper situated above the machine. All of our shot blast media hoppers come with a screen to prevent larger debris from entering the shot blast wheel.

Optional Rotary Screen Our standard lower and upper screens feature a 1/2” mesh size. We provide the option of adding a Rotary Screen. The Rotary Screen consists of a metal drum with 1/4″ perforations and an internal auger, specifically designed to effectively screen larger debris from the Media and discharge it out of the system. The screened Media then proceeds through to the hopper.

Abrasive Control Valve Totally enclosed butterfly valves are air cylinder operated. Fully adjustable for abrasive flow control.

Abrasive Separator The optional Single 10” Lip Separator, also known as a media air wash, efficiently removes fines and dust from blasting media, ensuring only clean, heavy media is recycled through the shot blast wheel. As media is returned to the hopper above the blast wheel, it spreads into a waterfall, creating a thin blanket of flowing media. A dust collector then pulls air across this stream, eliminating unwanted particles and allowing clean media to return to the abrasive hopper, ready for reuse. This process maintains high-quality blasting media, enhancing the effectiveness and longevity of the blasting operation.

Abrasive Required 300 pounds.

VENTILATION

Dust Collection Effectively eliminates dust-laden air from the machine, ensuring a cleaner work environment. Able to be incorporated with a single 10-inch lip separator that efficiently separates fines and dust from larger abrasives, keeping the media clean as it is returned to the blast system. The machine requires a 800 CFM dust collector, sold separately. Collector control circuit pre-wired on all Cardinal Shot blasters for easy integration.

ELECTRICAL CONTROLS

Control Panel:

- Type 12 electrical enclosure.

- Thermal overload protection for all motors.

- Standard 230/460 volt ammeter.

- Oil tight push button controls.

- Timer controls the abrasive flow.

- Touch Screen PLC Controls.

Safety Features The blast wheel operates exclusively when the door is shut. An air lock mechanism ensures that the cabinet door remains securely closed throughout the blasting process. With an adjustable time delay feature, the flow of abrasives serves as a brake on the blast wheel before the door can be safely opened.

ELECTRIC MOTORS All motors are totally enclosed, and fan cooled to provide maximum life. Optional 230/460 volt 3-phase.

.

Blast Wheels (2) 5 Hp/3510 RPM – 12.02amps @ 460 volts

Carousel Drive 1/2 Hp/1725 RPM – 1.0amps @ 460 volts

Elevator Drive 3/4Hp/1800RPM – 1.3amps @ 460 volts

Hook Spindle Drive 1/2 Hp/1140 RPM – 1.0amps @ 460 volts

Optional Rotary Screen 1/2 Hp/1725 RPM – 1.0amps @ 460 volts

Optional Dust Collector 3Hp/3600RPM – 6.3amps @ 460 volts

Noise Level Approximately 85 db.

Shipping Weight Approximately 4,650 pounds.

Dimensions:

- Width: 62”

- Depth: 56”

- Height: 139”