Jenfab 36″ Wide Belt Washer – Pre Owned

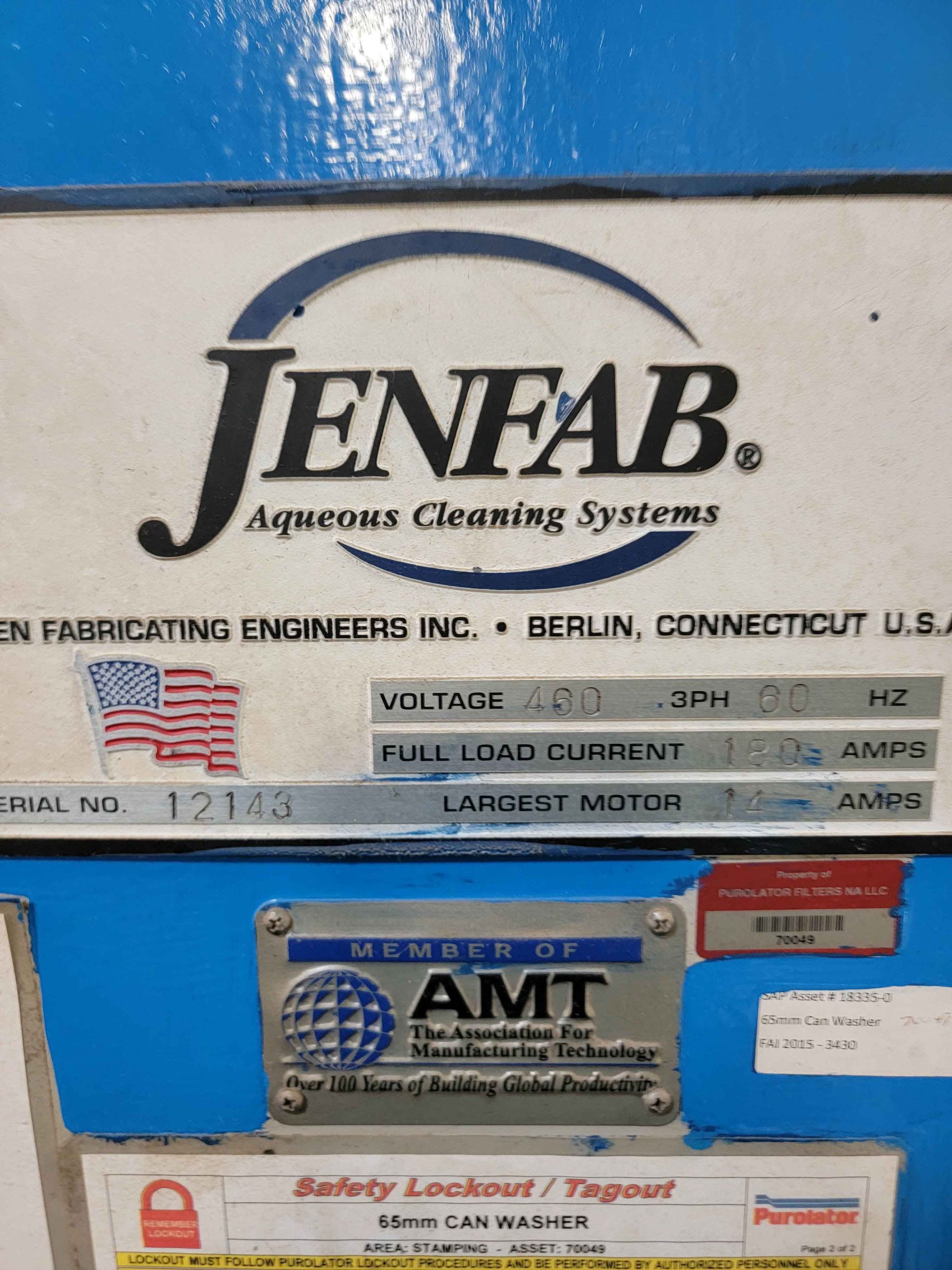

Brand: Jenfab Cleaning Solutions

Serial Number: 12143

Model: 36″ HD Belt

Year: 2011

Notes: This unit is in near new condition. Manufactured at the original Jenfab Connecticut location. It was purchased for a job that was shipped to China only months after receiving the washer. Manuals, cad files, electrical drawings, serial numbers are all available. This unit is heated by natural gas, includes tons of upgrades and options. Lots of pictures available.

Stages as follows: Complete stainless steel wetted construction

Belt Width: 36”

Tunnel Height – 4 1/2″ above belt

Total Length – 480″

Load and Unload height – 48″

Load / Unload combined length – 21″

Entry Vest. 1 – 24″

Spray Zone 1 – 24″

Drain Zone 1 – 30″

Spray Zone 2 – 18″

Drain Zone 2 – 30″

Spray Zone 3 – 18″

Drain Zone 3 – 36″

Spray Zone 4 – 60″

Drain Zone 4 – 30″

Spray Zone 5 – 18″

Drain Zone 5 – 30″

Spray Zone 6 – 18″

Drain Zone 6 – 18″

Dry Zone heated – 84″

All Tanks – 5 HP, Stainless Steel, Vertical Seal-less Gusher Pumps

All Spray Zones – top and bottom spray, with quick disconnect nozzles

Tank 1 – single 8×30 filter

Tank 4 – dual, in parallel filters, 8″ x 30″

Tank 1/2/4 – Marine door, side tank access ports

Tank 1 – 85 gallon Floor Mount Oil Coalescer

Tanks 1,2,3 – Eclipse IJ-6, 2MM BTU Gas Burner immersion tube – shared sized for 140F

Tank 4/5 – Eclipse, IJ-6, 2MM BTU Gas Burner immersion tube – shared sized for 140F

Tanks 6 – electric heat, 84kW, CCI Thermal Tech – L Shaped electric heater, 140F

Dryer – 10HP Chicago Blower, 12,000CFM – Eclipse Gas fired air burner, up to 250F

All Spray bars Stainless Steel, nozzles SS, throttling valves SS

Infeed water lines copper, with brass ball valves

Autowater fill controlled by float switches in each tanks, Tank 3,5,6 solenoid fill controls

Tank 1 make up from Tank 2 spray, Tank 2 make up from tank 3 via counterflow partition

Tank 4 make up from Tank 5 counterflow partition

Common main drain plumbing, 3″

Low Level float switches to protect gas burner and electric heat

Variable belt speed 2 fpm – 5 fpm

Relay logic control

All temperatures managed via RTD probes, digital thermostats, and chromalox high temp cont.

Steam Exhaust, 15″ diameter 1 hp, tube axial fan – 2000 CFM

Side Access Panel, removeable all zones.