Swing Frame Grinders

A swing frame grinder is a type of heavy-duty grinding machine commonly used in foundries for various operations. It features a motorized grinding wheel mounted on a swinging arm, allowing operators to easily move the wheel across workpieces of different shapes and sizes. These grinders are utilized for tasks such as removing excess material, smoothing surfaces, and shaping metal castings.

In foundry settings, swing frame grinders are employed to remove gates and risers from castings, clean up welds, and prepare surfaces for further processing or finishing. They are robust and powerful machines designed for industrial applications, offering full lateral movement for efficient grinding, polishing, or buffing. This equipment plays a vital role in foundries and steel mills for enhancing productivity and achieving desired surface finishes on workpieces.

Finishing Rx offers a variety of swing frame grinders configurations at three levels depending on the application needs: compact, medium-duty and heavy-duty.

Compact and Medium-Duty Swing Frame Grinders

Compact and medium-duty Swing Frame Grinders work well on large parts where portable grinders are now being used. They are not as maneuverable as portable grinders, but they are more aggressive. If the workpiece can be positioned so the area to be ground can be near the top, these grinders can do a quick and efficient job. They can also be swiveled up to 90 for angle or side grinding. Compact Units are offered in 2 HP and 3 HP, while medium-duty are offered in 5 HP, and 7.5 HP drive configurations.

The compact duty, 72 series of grinders are manufactured by G&P Machinery. They feature 2 or 3 HP, 208/230/460, 3-phase, 60 hertz motors. Their compact design utilizes 2”, 2.5”, or 3” wide x 72” long abrasive belts.

The medium-duty, 90 series of grinders are manufactured by G&P Machinery. They feature 5 or 7.5 HP, 208/230/460, 3-phase, 60 hertz motors. Their compact design utilizes 2”, 3” or 4” wide x 90” long abrasive belts.

These grinders can be converted from swing frame grinders to lathe grinders, pedestal grinders, and plate/weld grinders with the proper accessories. The third wheel attachment can be used as a contact wheel or slack of belt polisher. Consult Finishing Rx for additional information.

Contact Wheels: The proper contact wheel is an important factor in any grinding application.

* 90 durometer serrated face for rapid stock removal.

* 70 durometer serrated face for general purpose grinding.

* 50 durometer serrated face for moderate stock removal and polishing

Heavy-Duty Swing Frame Grinders

The Heavy-Duty Swing Frame Grinders are robust and powerful machines designed for heavy-duty grinding, deburring, and surface preparation on large parts. With standard 10 HP and 15 HP drive configurations, and the option for custom 20 HP and larger drives, these...

Compact and Medium Duty Swing Frame Grinders

A swing frame grinder is a type of heavy-duty grinding machine commonly used in foundries for various operations. It features a motorized grinding wheel mounted on a swinging arm, allowing operators to easily move the wheel across workpieces of different shapes and...

Burr Bench Metal Finisher: Model 4616

The Burr-Bench® Metal Finisher distinguishes itself as the first portable deburring machine, renowned for its reliable performance, affordability, and versatility in managing a wide array of metal finishing tasks. From coarse grinding to delicate polishing, its...

Burr Bench Metal Finisher: Model 2016

The Burr-Bench® Metal Finisher distinguishes itself as the first portable deburring machine, renowned for its reliable performance, affordability, and versatility in managing a wide array of metal finishing tasks. From coarse grinding to delicate polishing, its...

Burr Bench Metal Finisher: Model 914

The Burr-Bench® Metal Finisher distinguishes itself as the first portable deburring machine, renowned for its reliable performance, affordability, and versatility in managing a wide array of metal finishing tasks. From coarse grinding to delicate polishing, its...

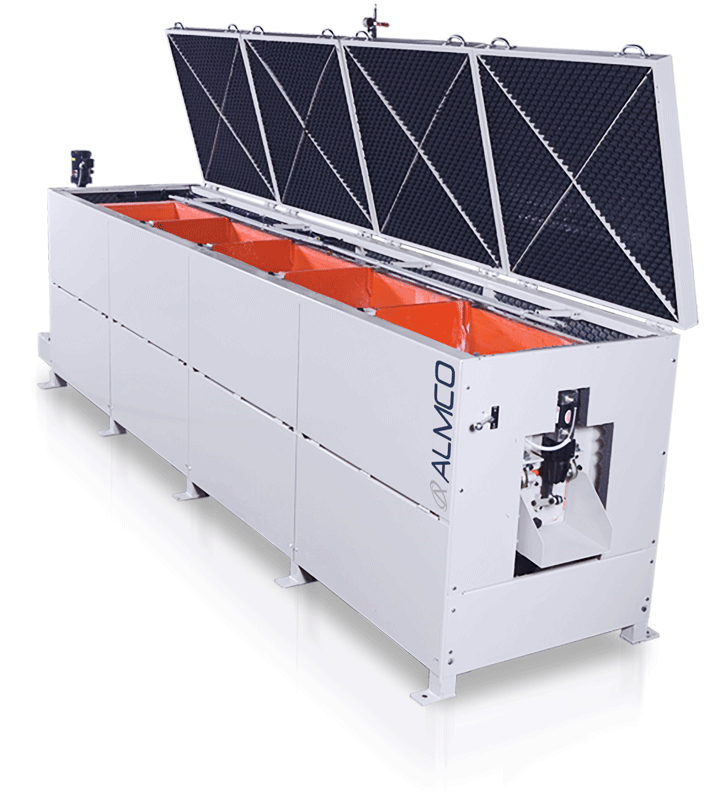

VB Series Vibratory Finishing Tubs

Introducing the Value Base (VB Series) vibratory finishing tubs by ALMCO, the epitome of cost-effective efficiency in industrial finishing. These robust and versatile machines are designed to deliver exceptional results at a lower price point, featuring simplified...

V Series Vibratory Finishing Tubs

The V Series Vibratory Tub finishing machines are heavy duty, robust units that are offered in various customizable configurations to meet specific requirements. These machines can be integrated into automated systems, reducing the need for manual intervention. They...

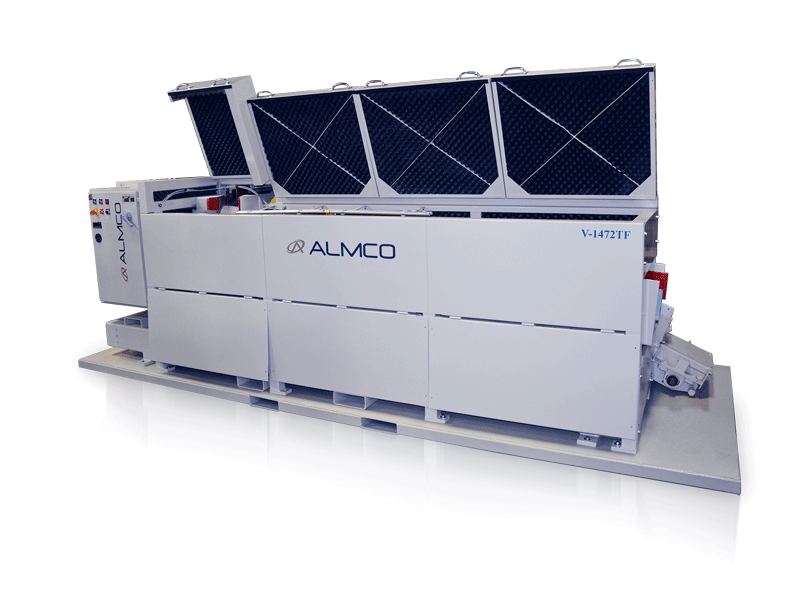

Inline Thru-Feed Vibratory Finishing Tubs

The Inline, Continuous Thru-Feed Series vibratory finishing tubs are renowned for their high production volume capabilities, making them essential equipment in various industrial finishing processes. These machines are integrated with advanced material handling...