Wastewater Treatment

Manufacturers play a critical role in managing wastewater, whether it’s for safe discharge into the sewer system or for recycling and reuse within their operations. Proper treatment is essential to eliminate harmful substances such as heavy metals and toxic chemicals, ensuring compliance with regulations and safeguarding public health and the environment. This process guarantees that the discharged water poses no threat to aquatic ecosystems or human populations.

An increasing number of manufacturers are now turning to the recycling of treated wastewater for internal use, reaping both environmental and financial rewards. Utilizing advanced techniques like membrane filtration and reverse osmosis, wastewater can be purified to a quality suitable for industrial purposes such as cooling and cleaning. This not only decreases the reliance on fresh water but also reduces wastewater discharge, resulting in substantial cost savings and promoting sustainable water management practices.

Finishing Rx offers cutting-edge treatment equipment, supplies, and procedures to empower your facility in water treatment. With a wide range of treatment solutions, assistance in compliance monitoring, and extensive experience in system implementation, you can confidently manage your water treatment needs.

Filter Presses

Wastewater pre-treatment in manufacturing is the process of treating wastewater from industrial activities before releasing it into the municipal sewage system. This pre-treatment is essential to eliminate contaminants, pollutants, and harmful substances from the...

Sludge Dewatering Filter Bed

Wastewater pre-treatment in manufacturing is the process of treating wastewater from industrial activities before releasing it into the municipal sewage system. This pre-treatment is essential to eliminate contaminants, pollutants, and harmful substances from the...

Sludge Dewatering Bag

Wastewater pre-treatment in manufacturing is the process of treating wastewater from industrial activities before releasing it into the municipal sewage system. This pre-treatment is essential to eliminate contaminants, pollutants, and harmful substances from the...

Continuous Flow Wastewater Treatment System

Continuous flow wastewater pretreatment in manufacturing treats wastewater continuously to remove contaminants before discharge. It involves physical, chemical, and biological processes to clean the water and is preferred over batch treatment for several reasons....

Batch Wastewater Treatment System

Batch-style treatment in wastewater pre-treatment involves treating a specific volume or "batch" of wastewater at a time, rather than continuously. This method allows wastewater to be collected in a tank, treated to remove contaminants, and then discharged or further...

Centrifuge Process Water Recycling

A centrifuge is essential for separating solid particles from liquids like vibratory finishing water. The centrifuge works by rapidly spinning the mixture, creating a centrifugal force that drives solid particles to the outer walls, while clarified water is...

Sediment Tank

The ALMCO Sediment Tank is a very cost-effective solution for users that have a single deburring machine. These tanks may be used to allow solids to settle out prior to discharge into the drain or they may be equipped with a pump to recirculate liquid to the finishing...

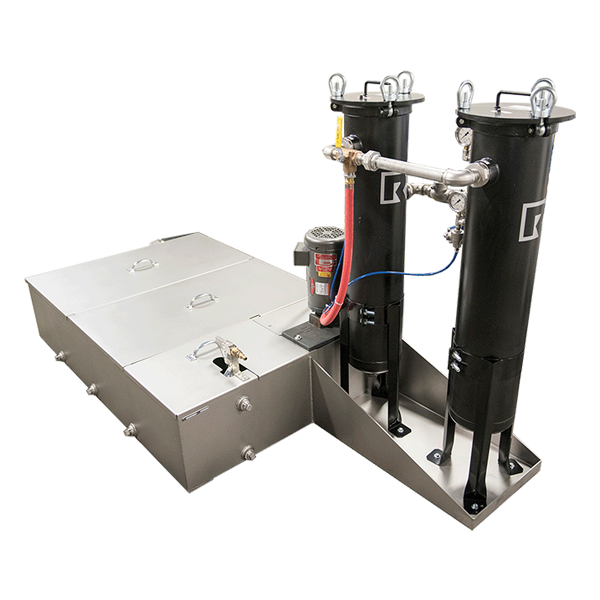

ARS1500

Our batch process water recycling equipment offers manual and semi-automated processes designed to provide your finishing equipment with cleaned, recycled water for reuse in the deburring operation. All of the water recycling units are constructed with stainless...

ARS1000

Our batch process water recycling equipment offers manual and semi-automated processes designed to provide your finishing equipment with cleaned, recycled water for reuse in the deburring operation. All of the water recycling units are constructed with stainless...

TC250

Our batch process water recycling equipment offers manual and semi-automated processes designed to provide your finishing equipment with cleaned, recycled water for reuse in the deburring operation. All of the water recycling units are constructed with stainless...

Oil Coalescer

An oil coalescer separates oil from water or other fluids by coalescing small oil droplets into larger ones, which are easier to separate due to their increased buoyancy. The process involves the mixture passing through oleophilic and hydrophobic media, causing...