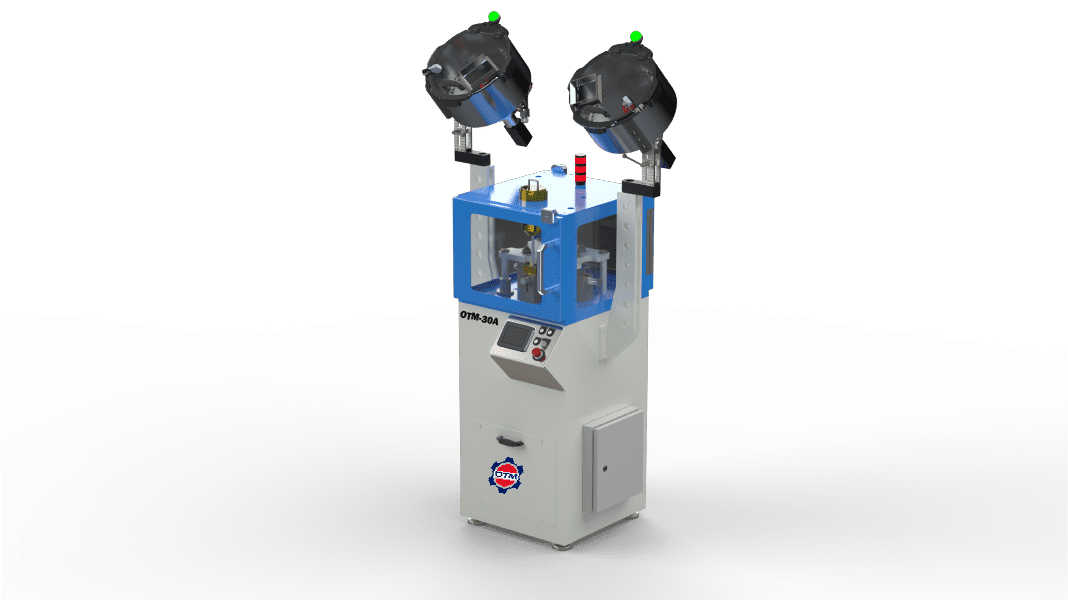

OTM – 30A/B

The OTM-30A and OTM-30B are specialized loading machines designed for different types of cartridges in the manufacturing industry.

– Type: Single powder drop pistol cartridge loading machine

– Max production capability: 60 parts per minute

– Designed for loading pistol cartridges efficiently

– Suitable for companies of various sizes

– Features a 5″ color touch screen for easy operation

– Equipped with physical touch buttons for operator interfacing

– Optional features include overall length check and powder check

– Requires 110V power and 100 PSI air

– Compact footprint: 48″ x 36″

– Weight: 950 lbs

OTM-30B:

– Type: Dual powder drop rifle cartridge loading machine

– Max production capability: 50 parts per minute

– Designed for loading rifle cartridges with precision

– Features a quick-change system for increased flexibility

– Ensures operator safety with magnetic door interlocks

– Complete guarding with 1/4″ polycarbonate windows for visibility

– Stationary powder hopper for easy refill during operation

– Equipped with a mechanical indexer for position repeatability

– Requires 110V power and 100 PSI air

– Compact footprint: 48″ x 36″

– Weight: 950 lbs

Both machines are built to run at lower run rates and offer easy tooling conversions to cater to the specific needs of the end user. They are designed to provide efficient and reliable performance for cartridge loading operations in manufacturing facilities.

| Caliber | Powder Drops in Use | Production rate | Average Efficiency |

| 9 MM | 1 | 75 ppm | 90% |

| 45 ACP | 1 | 75 ppm | 90% |

| 300 AAC | 2 | 65 ppm | 90% |

| 5.56×45 | 2 | 60 ppm | 90% |

| 308 WIN | 2 | 60 ppm | 90% |

| 338 LAPUA | 2 | 45 ppm | 90% |