CPC12000

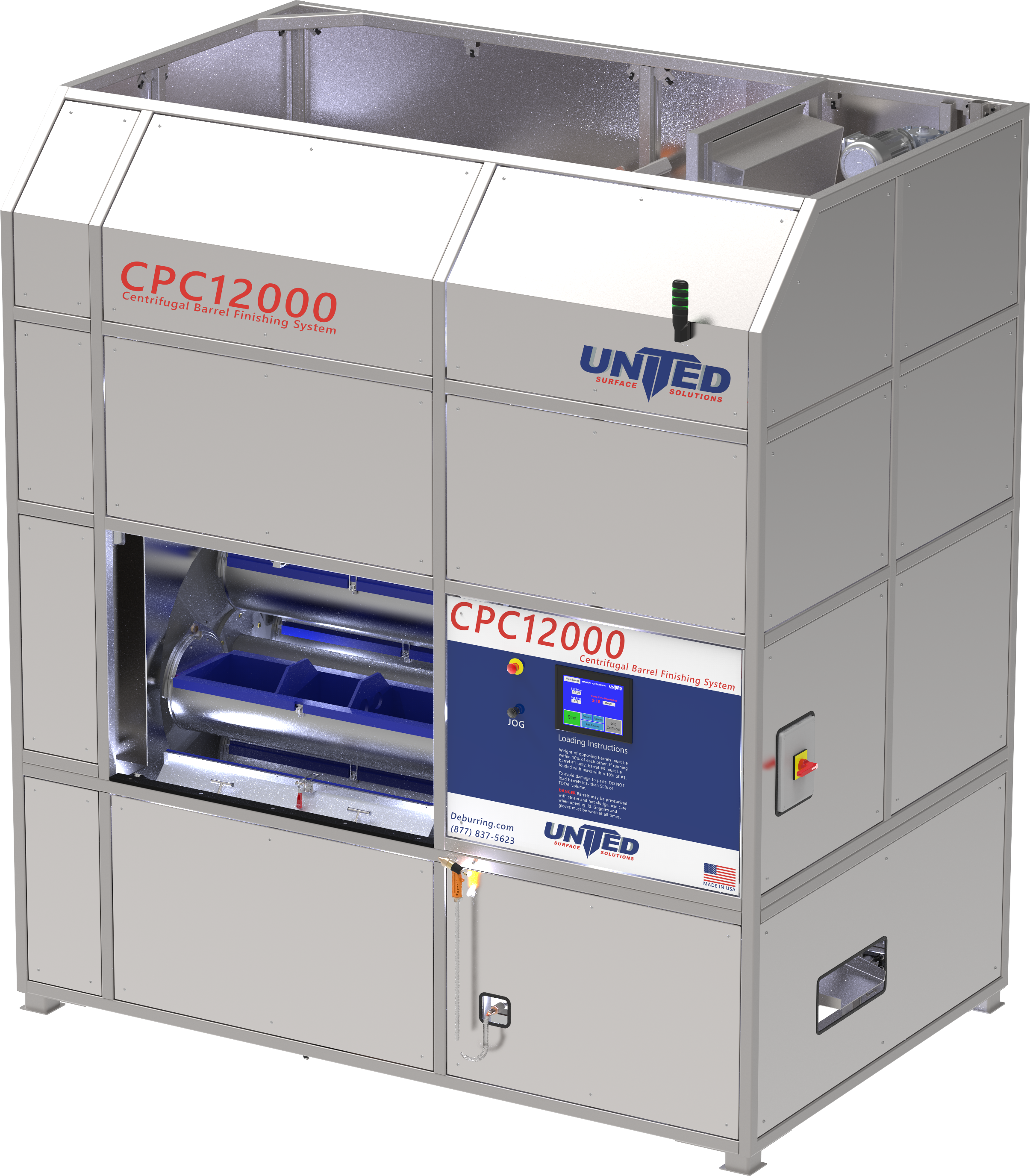

Introducing the United CPC12000, the pinnacle of precision automated deburring systems and the largest, most automated centrifugal barrel system in the market. Designed for efficiency and performance, the CPC12000 offers unparalleled capabilities for processing parts with speed and accuracy. The system’s advanced automation for barrel positioning, lid lifting, parts separation, and cleaning, all controlled through an intuitive touchscreen interface, ensures optimal performance and consistency in deburring processes.

The CPC12000 stands out for its customization and efficiency, offering a cost-effective solution for deburring and mass finishing by processing larger parts or multiple smaller parts in the shortest cycles. Its customizable features allow for tailored solutions to meet specific needs, optimizing efficiency and throughput. Equipped with a PLC and touchscreen, the CPC12000 simplifies operation and management of processes, storing and recalling detailed process information to enhance productivity and workflow management.

With its user-friendly design, including a touchscreen display, process storage capabilities, and easy maintenance features like removable body panels and replaceable parts, the CPC12000 enhances usability and convenience for operators. Businesses can optimize their deburring processes for efficiency, precision, and reliability by leveraging the advanced features and capabilities of the United CPC12000. Highlighting these key features with a focus on search engine optimization will attract potential customers seeking advanced deburring solutions in the market.

Model Class: Standard Fully Auto / High Capacity / Wide Diameter

Max part size: 44” L x 12” D

Barrel Dims: 44.5” L x 12.5” D

Common Parts: Die Cast, Metal Stampings, Aerospace, Fabricated Parts

Voltage: 480V

Total Capacity: 12 cubic feet

Max RPM: 175 RPM

Footprint: 81” x 124” x 138”