Drum Blast Systems

Finishing Rx introduces the Cardinal Parts and Equipment line of Drum Shot Blasters, designed for optimal surface preparation and finishing processes. These machines, also known as barrel blasters, utilize a manganese drum to tumble parts gently while exposing them to a continuous stream of abrasive media such as steel shot or grit. This process ensures thorough cleaning, deburring, descaling, and surface preparation of metal parts, making them ideal for various industrial applications.

Drum Shot Blasters are crucial for industries that require cleaning, rust removal, and surface strengthening of metal parts. They excel in preparing surfaces for painting, plating, or coating by efficiently removing rust, scale, and other contaminants. These machines are perfect for processing a wide range of parts, including castings, forgings, and small to medium-sized components with complex geometries that benefit from the tumbling action.

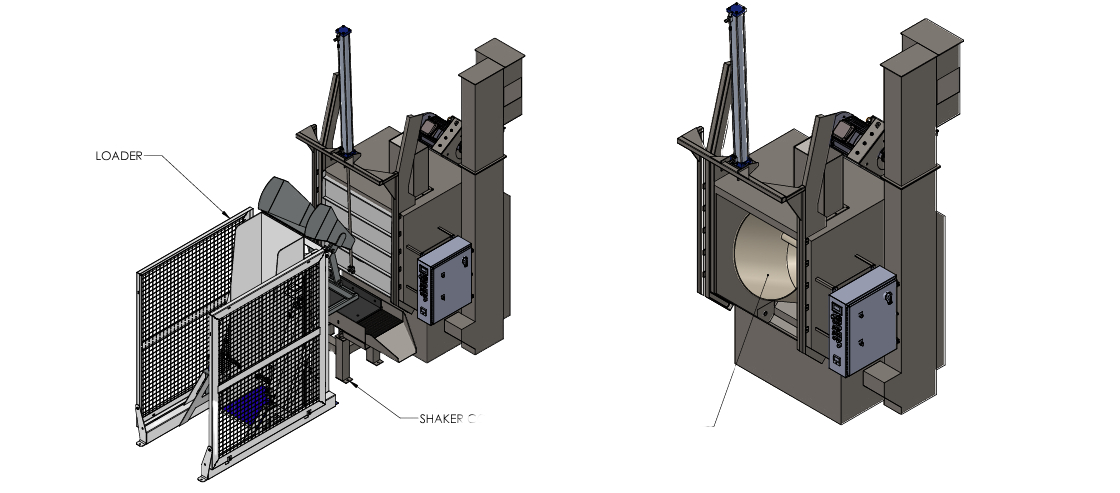

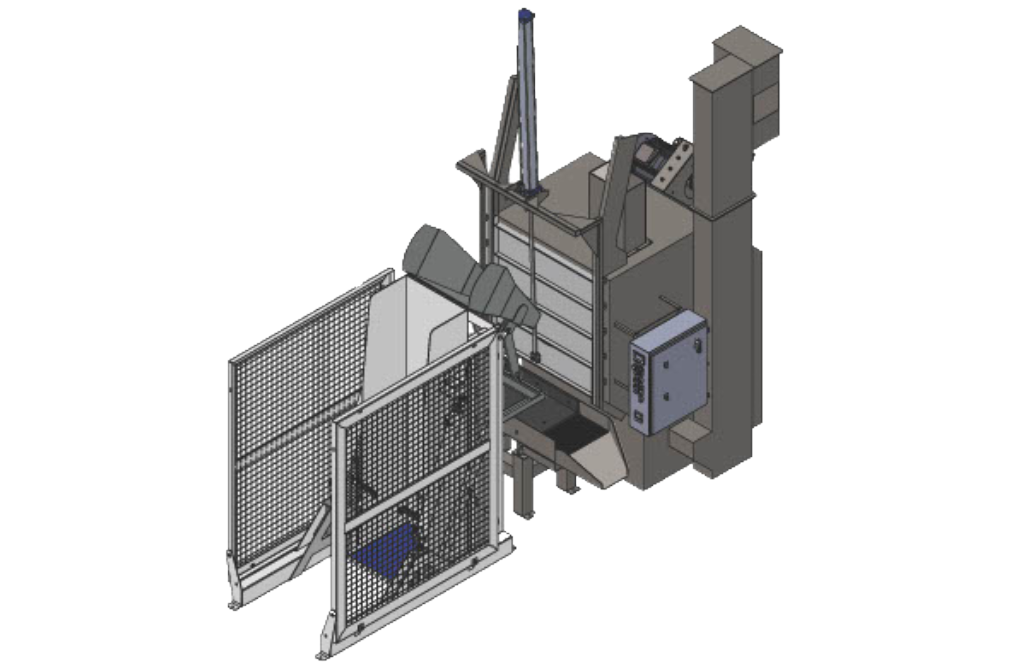

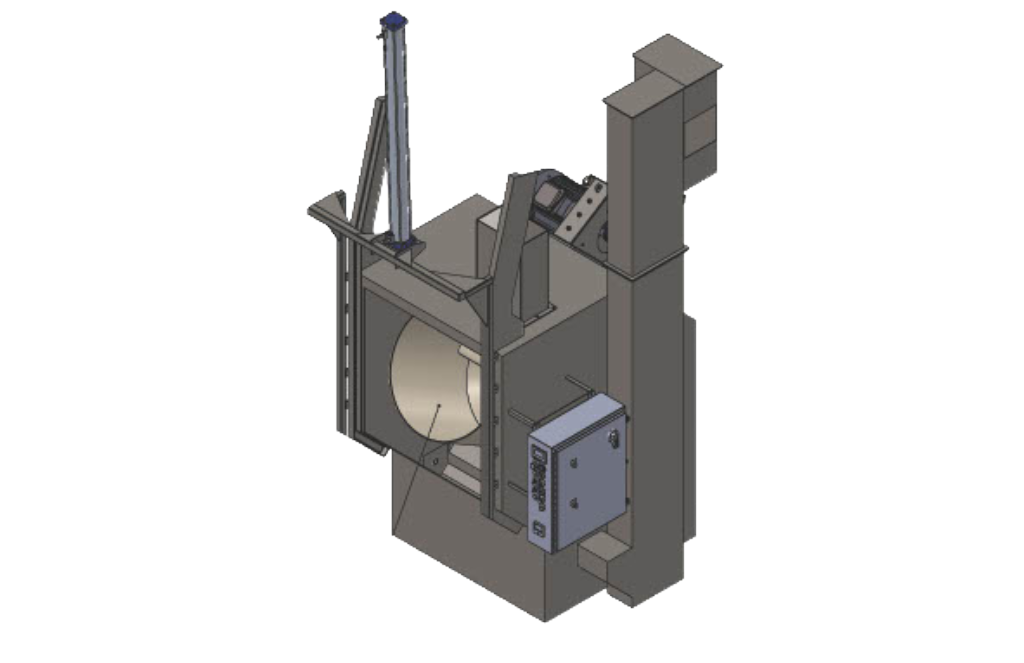

One of the key advantages of Cardinal Drum Shot Blasters is their innovative design, which significantly reduces maintenance costs and downtime compared to traditional flighted mill belt, tumble blast equipment. The single-piece drum construction prevents parts from jamming and ensures complete emptying, avoiding reprocessing of workpieces. This design not only enhances efficiency but also extends the machine’s lifespan.

Cardinal Drum Shot Blasters are equipped with advanced features that set them apart from conventional blast machines. The standard Cardinal direct drive wheel with an easy-to-change snap lock blade design ensures smooth operation. The zero pinch design eliminates part jams, reducing part damage and enhancing overall productivity. Available in sizes of 5 cubic feet, 8 cubic feet, and 12 cubic feet, these machines cater to varied industrial needs.

For even greater efficiency, Drum Shot Blasters can be integrated with hydraulic loaders and takeaway conveyors, transforming them into fast, batch-style machines. This integration reduces the need for material handling and operator involvement, speeding up the blasting cycle and saving energy. The advanced design also includes features like automatic dumping drums, pneumatic controlled vertical doors, and a no-leak construction that ensures a clean and safe work environment.

Constructed from perforated manganese steel, the drums are designed for long-term durability and wear resistance. The machines are suitable for a variety of applications, including sand removal, rust removal, descaling, and surface strengthening of castings and forgings. Their robust construction and efficient design make them ideal for handling mass-produced small and medium-sized parts in various industries.

Cardinal Drum Shot Blasters, available through Finishing Rx, represent a significant advancement in surface preparation technology. Their efficient operation, low maintenance requirements, and advanced features make them an excellent investment for industries seeking reliable and effective surface treatment solutions. By choosing Cardinal Drum Shot Blasters, businesses can enhance their operational efficiency, maintain superior product quality, and achieve consistent, high-quality finishes. Contact Finishing Rx today to learn how these machines can revolutionize your surface preparation processes.

CARDINAL 12 CU-FT DRUM BLAST

The Cardinal Drum Shot Blasters offered by Finishing Rx are designed for optimal surface preparation, utilizing a manganese drum and a high powered blast wheel to clean, deburr, descale, and prepare metal parts with abrasive media like steel shot or grit. These...

CARDINAL 8 CU-FT DRUM BLAST

The Cardinal Drum Shot Blasters offered by Finishing Rx are designed for optimal surface preparation, utilizing a manganese drum and a high powered blast wheel to clean, deburr, descale, and prepare metal parts with abrasive media like steel shot or grit. These...

CARDINAL 5 CU-FT DRUM BLAST

The Cardinal Drum Shot Blasters offered by Finishing Rx are designed for optimal surface preparation, utilizing a manganese drum and a high powered blast wheel to clean, deburr, descale, and prepare metal parts with abrasive media like steel shot or grit. These...