Ammunition Manufacturing Equipment

Ammunition manufacturing equipment is essential for the production of firearm cartridges, ensuring quality, efficiency, and consistency throughout the process. Finishing Rx is proud to present the “On the Mark” line of Ammo Manufacturing Equipment, which includes offerings such as Cartridge Loaders, Case Feeders, Case Priming machines, and Head Turn & Trim Equipment.

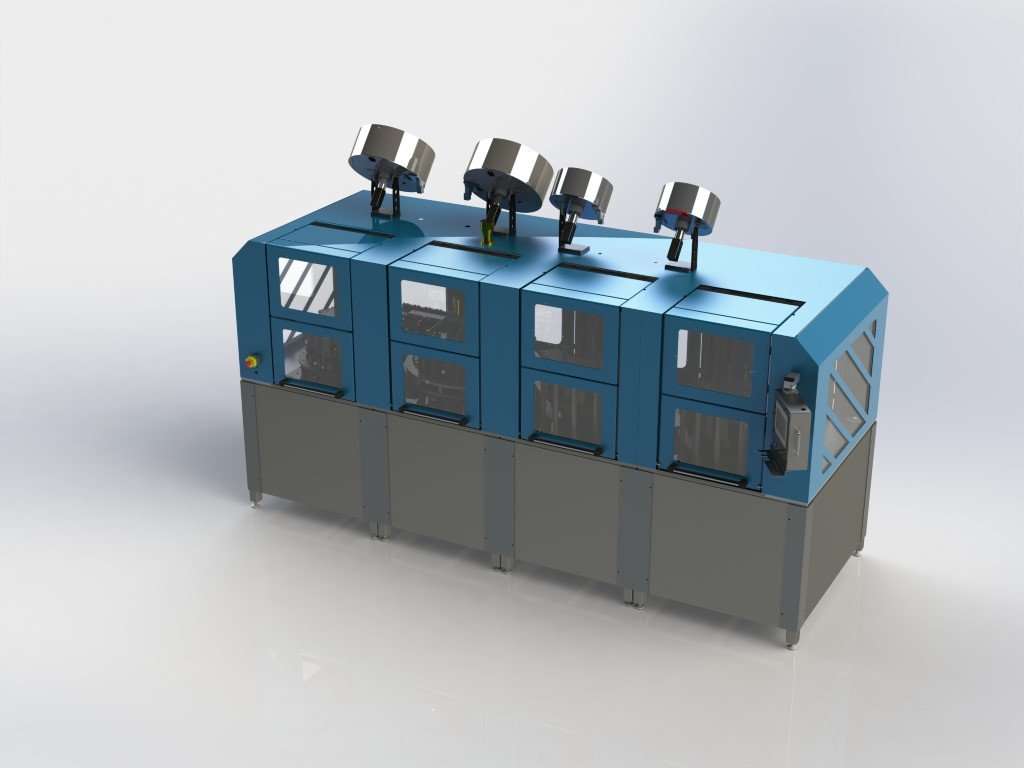

Cartridge loaders are available in various configurations, ranging from manual to fully automated systems, to meet different production scales and requirements. These machines streamline the assembly process, boosting productivity and minimizing human error.

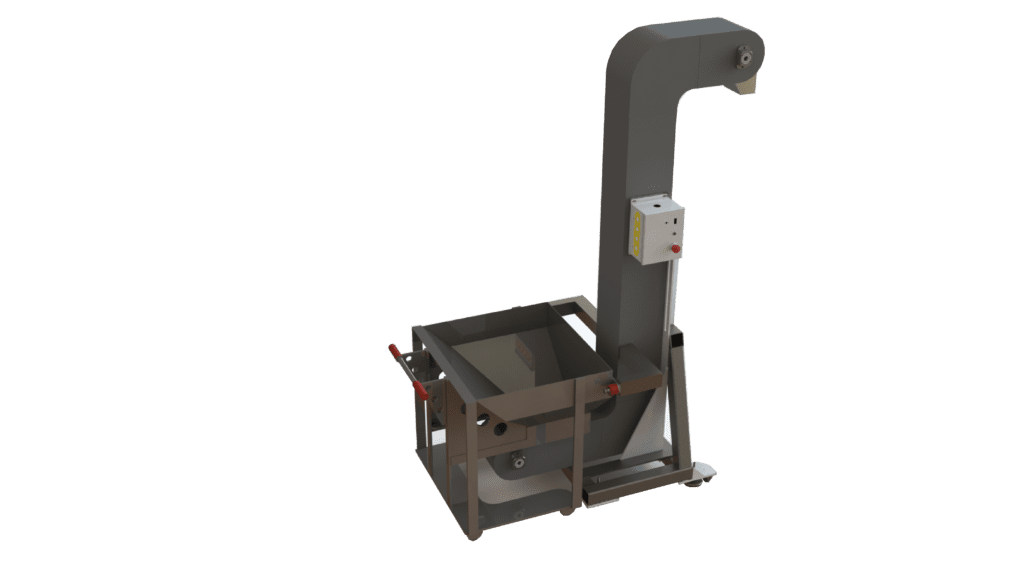

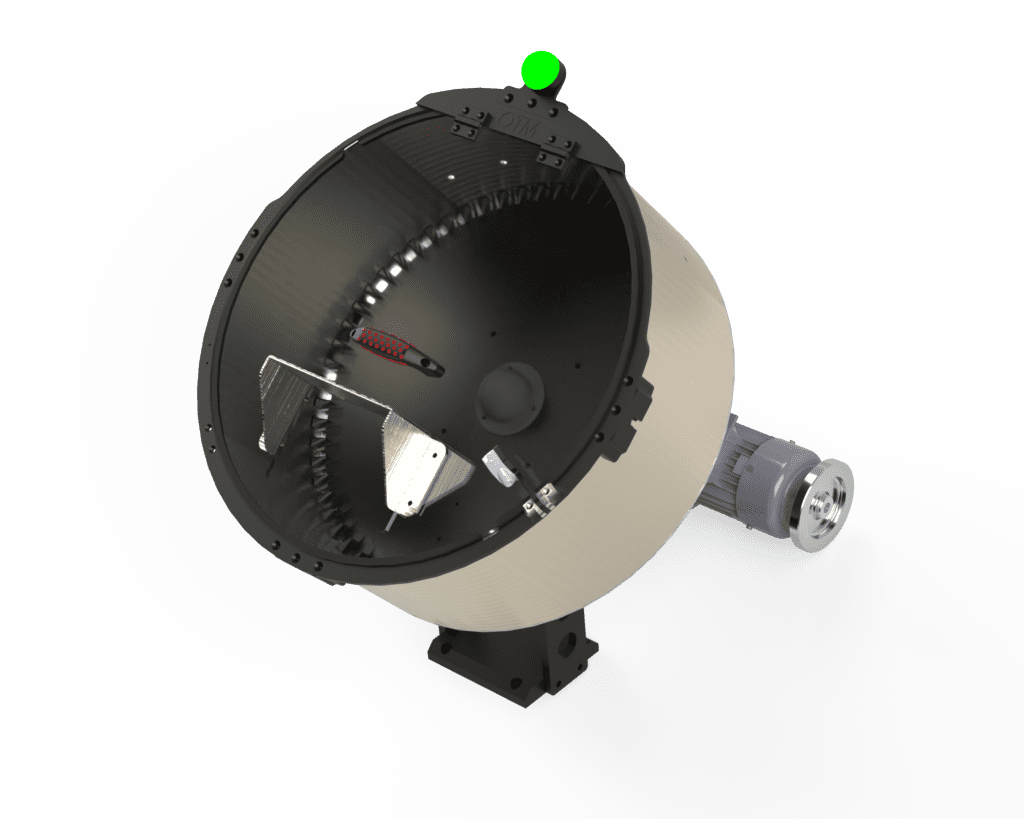

Case feeders are designed to automatically supply empty cartridge cases into the production line, saving time and labor compared to manual feeding. By providing a continuous flow of cases, these feeders help maintain a consistent workflow and prevent production delays.

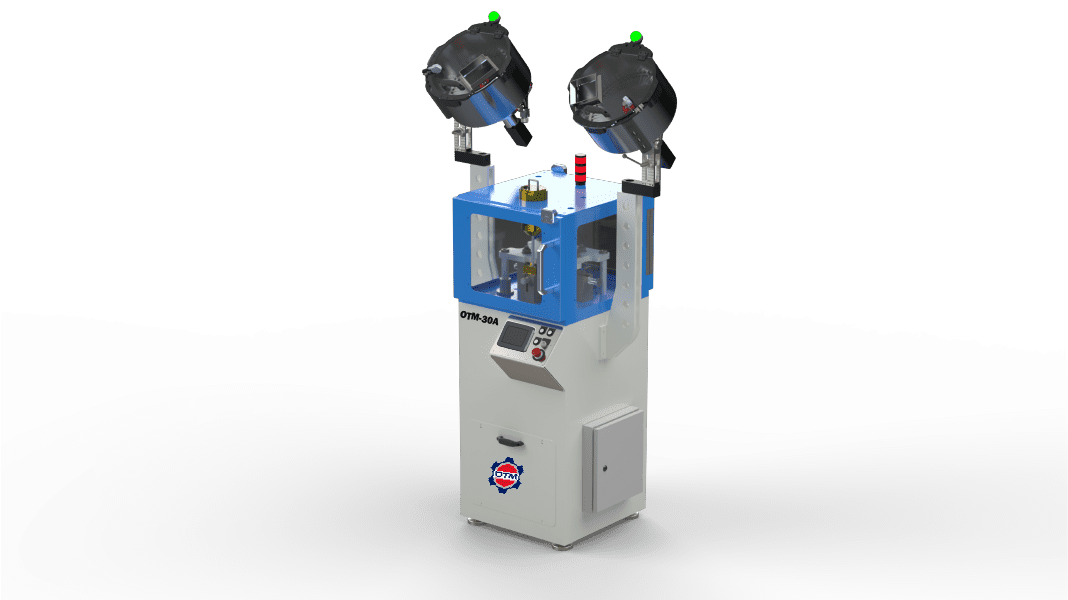

Case priming is a crucial step in ammunition manufacturing, ensuring that the primer is correctly seated in the base of the cartridge case. Dedicated case priming machines accurately and securely insert and seat primers, reducing the risk of misfires and other safety issues.

Head turn and trim equipment is used to trim and chamfer the necks of cartridge cases, ensuring they meet the specified length and dimensions for proper chambering and firing in firearms

Finishing Rx offers specialized equipment like cartridge loaders, case feeders, case priming machines, and head turn & trim equipment that are vital for the efficient and precise production of ammunition. By leveraging advanced equipment, ammunition manufacturers can enhance their production capabilities, ensure the quality and consistency of their products, and effectively meet market demands.