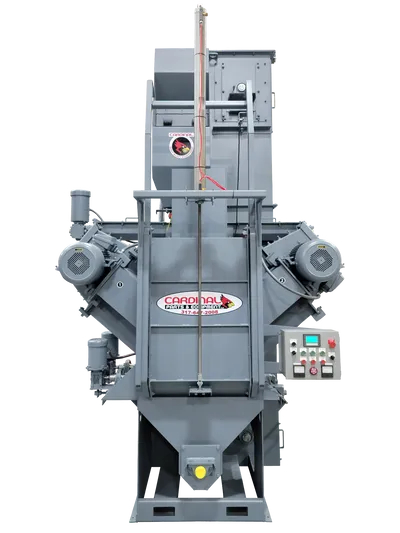

Cardinal Rim Blaster

Introducing the Cardinal Rim Blaster, a cutting-edge solution for prepping automotive wheels using wheel blasting technology. Specifically designed for rims ranging from 16 to 26 inches in diameter, this machine is capable of efficiently removing OEM powder coat without causing damage to the substrate.

Equipped with two powerful 20HP 15-inch diameter wheels, a pneumatic vertical door, and cast liners for machine protection, the Cardinal Rim Blaster ensures optimal performance and durability. Additionally, it features an air wash fines separator that effectively removes dust and fines from the media.

With wheels mounted on both the left and right sides of the equipment, this innovative blaster guarantees complete coverage on even the most complex rim geometries, enabling quick processing in just minutes. The heavy-duty blast-resistant rollers provide a stable platform for the rims, while the included PLC/HMI controller and timer offer user-friendly operation and control.

Experience efficiency and precision like never before with the Cardinal Rim Blaster — the ultimate solution for automotive wheel preparation.

– (2) 20 Hp Direct Drive Blast Wheel Assy.

– Blasts 12″-26″ Rims

– 15″ Diameter Blast Wheels

– Electrical 460/208/3ph

– Plc Controlled Timer

– Low Noise Level

– Safety Interlocks

– Pneumatic Lift Door

– Manganese Door

– Cast Lined in Blast Zones, Balance is Manganese

– Airwash Separator

– Low Level Sensor, Shield, Indicator Light

– 5″ Elevator Belt with Cast Buckets

– 1200 CFM Dust Collector (55 Gallon Legs)

CENTRIFUGAL BLAST WHEEL

WHEEL: Two efficiently designed single-sided blast wheels minimizes the overhung load on the motor and reduces the time required to change blades, impellers, and control cage. The standard blast wheel measures 12” in diameter and features seven curved blades for optimal abrasive control. All components are balanced to ensure smooth operation. With a high horsepower-to-weight ratio, this system enhances abrasive delivery efficiency per unit of horsepower.

MOTOR: Direct drive motor revolves at 3600 RPM. Taper lock brushed motor shaft with NEMA tolerance.

BLADES: Our innovative Snap Lock system simplifies blade replacement without the need for tools. Crafted from abrasion-resistant alloy in our in-house foundry, our curved blades offer optimal abrasive control. Cardinal shot blast wheels allow for effortless blade replacement in sizes 12”, 13.5”, or 15”, enhancing shot velocity and increasing versatility.

CONTROL CAGE: Dial type cage for ease of targeting the abrasive flow.

WHEEL HOUSING:Our wheel housings are made from durable steel plate and are fully lined with replaceable cast chrome manganese alloy liners produced in our own foundry.

CABINET CONSTRUCTION

CABINET: Crafted from durable 1/4” steel plate, our cabinet construction promises unparalleled durability and reliability. Thoughtfully designed access holes on the sides make belt and liner replacement a breeze, enhancing maintenance efficiency. Additionally, tramp metal is effectively captured on lower abrasive screens, ensuring that large debris is meticulously filtered out before it can reach the abrasive hopper, maintaining optimal blasting performance and equipment longevity.

DOOR: Abrasive resistant door is secured by an air operated power lock.

ABRASIVE RECYCLING SYSTEM

BUCKET ELEVATOR:Our belt and bucket elevator features centrifugal discharge and is outfitted with a 5-inch elevator belt along with cast buckets. The screw-adjusted shaft take-ups guarantee accurate belt alignment. The abrasive shot blast media is efficiently conveyed by the buckets to the hopper positioned above the machine, where the media will flow to the shot blast wheel.

ABRASIVE CONTROL VALVE: Totally enclosed butterfly valves are air cylinder operated. Fully adjustable for abrasive flow control.

ABRASIVE SEPARATOR:The Single 20” Lip Separator, also known as a media air wash, efficiently removes fines and dust from blasting media, ensuring only clean, heavy media is recycled through the shot blast wheel. As media is returned to the hopper above the blast wheel, it spreads into a waterfall, creating a thin blanket of flowing media. A dust collector then pulls air across this stream, eliminating unwanted particles and allowing clean media to return to the abrasive hopper, ready for reuse. This process maintains high-quality blasting media, enhancing the effectiveness and longevity of the blasting operation.

ABRASIVE REQUIRED: 2000 pounds.

VENTILATION

DUST COLLECTION: The Cardinal Rim Blaster features a 1200 CFM dust collector, effectively eliminating dust-laden air from the machine to ensure a cleaner work environment. It also includes a single 20-inch lip separator that efficiently segregates fines and dust from larger abrasives, maintaining the cleanliness of the media as it cycles back into the blast system. Additionally, the machine is equipped with a pre-wired collector control circuit on all Cardinal Shot blasters, making integration and operation seamless.

ELECTRICAL CONTROLS

CONTROL PANEL:

- Type 12 electrical enclosure.

- Thermal overload protection for all motors.

- Standard 230/460 volt ammeter.

- Oil tight push button controls.

- Timer controls the abrasive flow.

- Touch Screen PLC Controls.

SAFETY FEATURES: The blast wheel operates exclusively when the door is shut. An air lock mechanism ensures that the cabinet door remains securely closed throughout the blasting process. With an adjustable time delay feature, the flow of abrasives serves as a brake on the blast wheel before the door can be safely opened.

ELECTRIC MOTORS: All motors are totally enclosed, and fan cooled to provide maximum life. Optional 230/460 volt 3-phase.

Blast Wheel: (2) 20 Hp/3540 RPM – 46.20amps @ 460 volts

Roller Drive #1: .50 Hp/1725 RPM – 1.2amps @ 460 volts

Roller Drive #2: .50 Hp/1725 RPM – 1.2amps @ 460 volts

Elevator Drive: 2.0 Hp/1725 RPM – 2.96amps @ 460 volts

Optional Dust Collector: 3.0 Hp/3600 RPM – 3.8amps @ 460 volts

NOISE LEVEL: Approximately 85 db.

DIMENSIONS:

- Width: 102”

- Depth: 82”

- Height: 166”

SHIPPING WEIGHT: Approximately 5500 pounds.